3D-printed surgical solutions.

The SpinePrint Laboratory Project is founded by Dr Tess Reynolds, working in close collaboration with orthopaedic surgeon Dr Andrew Kanawati (Westmead Hospital). It is dedicated to delivering novel 3D-printed solutions to the treatment of disease, currently focused on applications in oncology and orthopaedics.

Surgical Guides

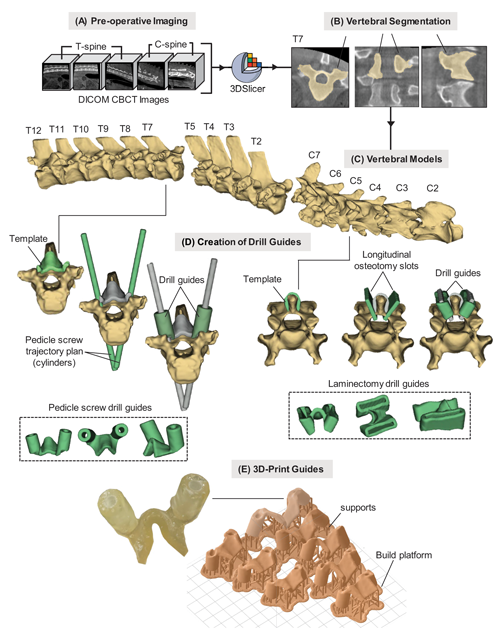

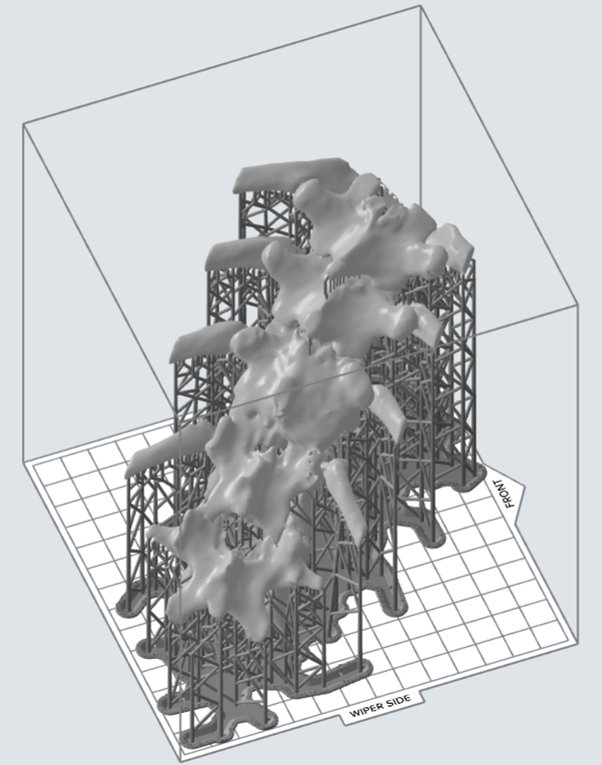

Accurate drilling and cutting are fundamental to successful and efficient surgical procedures. 3D-printed surgical guides are increasingly being used clinically to complement surgeon experience, allowing pre-planning of drilling and cutting that takes into consideration individual anatomical characteristics. To date, 3D-printed surgical guides have been predominately developed from preoperative CT and MRI scans.

Working in collaboration with Dr Andrew Kanawati, SpinePrint has been investigating the possibility of using robotic CBCT imaging systems to created 3D-printed surgical guides. Robotic CBCT systems are becoming common place in orthopaedic departments, facilitating diagnosis and treatment planning in the extremities (i.e. wrist, ankle, and knee) and are primed for expansion to other anatomical sites.

To date, we have examined the accuracy of developing 3D-printed surgical guides for spine stabilisation and laminectomy procedures. In animal cadaver models, the 3D-printed surgical guides demonstrated sufficient precision compared to those previously reported from CT.

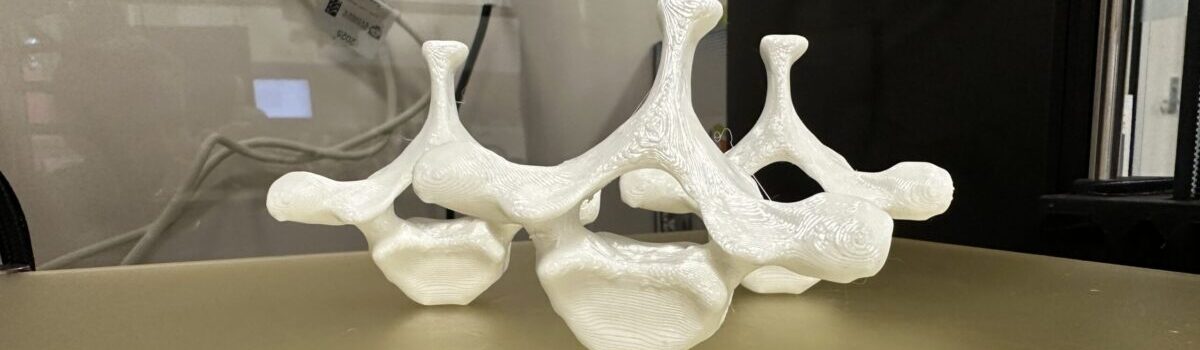

Guide printed by SpinePrint for use in clinical case

Anatomical Models

3D printed anatomical models provide a physical model of patient anatomy, allowing surgeons to improve pre-operative planning and provide a valuable physical asset to assist in treatment decision during the procedure. Anatomical models can also be used to educate and inform patients on their treatment.

May 2024: Lower thoracic vertebra model to assist full resection of spinal tumor on a paediatric patient.

Team Contact

For more information about the program and projects, contact Dr Tess Reynolds

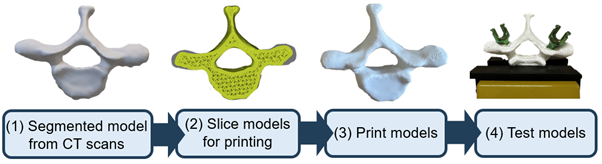

Synthetic Spines

Surgical proficiency requires unmatched levels of skill and knowledge, continuously being refined as new procedural techniques emerged. To supplement hands-on clinical experience, especially in rural, remote, and low socioeconomic settings, low-cost realistic alternatives to human cadavers need to be developed. Here, we look to design, develop, print, and test 3D printed synthetic spine models with realistic haptic feedback, biomechanical forces, and range-of-motion, replicating the anatomical and biomechanical properties of human bone. Synthetic spines will not only be a valuable tool in the early stages of a surgical career, but will also facilitate advanced surgical simulation, allowing patient-specific spine models to be 3D-printed for preparation and simulation prior to undertaking complex procedures.

The first spinal procedure we are targeting with synthetic spines is a pedicle screw fixation, commonly used to stabilise the spine of metastatic spine patients to relieve pain and improve quality of life.

Team Contact

For more information about the program and projects, contact Professor Paul Keall

Related Publications

Kanawati, A. Constantinidis, Z. Williams, R. O’Brien, and T. Reynolds, “Generating patient-matched 3D-printed pedicle screw and laminectomy drill guides from Cone Beam CT images: studies in ovine and porcine cadavers”, Medical Physics 49 (7), 4642-4652, 2022.